Technical Specifications

Important Notes & Considerations

Optimal Thickness: Recommended for production with good cutting speed (typically ≥1 m/min) and excellent quality. Represents the best balance.

Maximum Thickness: Physical cutting limit. Speed may be significantly lower (<0.5 m/min) and edge quality reduced (more dross, rougher finish). Use when maximum penetration is the priority.

Carbon Steel: Oxygen (O₂) cutting provides the highest efficiency and thickness capability, but may leave an oxide layer on the edge.

Stainless Steel & Aluminum: Nitrogen (N₂) cutting prevents oxidation, resulting in bright, clean edges suitable for welding without further treatment. It requires higher gas pressure and potentially higher laser power compared to O₂ cutting for the same thickness.

Gas Purity: For N₂ cutting, high purity (≥99.99%) is crucial for achieving clean, oxide-free edges.

Material Quality: The actual results depend heavily on the specific grade, surface condition (rust, oil), and internal consistency of the material being cut.

Machine Setup: Performance relies on correct parameter settings (focus position, nozzle type/size, gas pressure, speed) specific to the material and thickness.

General Reference: These charts serve as a general guideline based on Max Photonics laser sources. Testing with your specific material is recommended for critical applications.

Frustrated with Traditional Production Bottlenecks?

Rising costs of ink and consumables.

High labor dependency.

Inconsistent quality and output.

The Future is Automated Laser Technology.

Drastically reduce consumable costs.

Increase output without adding staff.

Achieve flawless, repeatable precision.

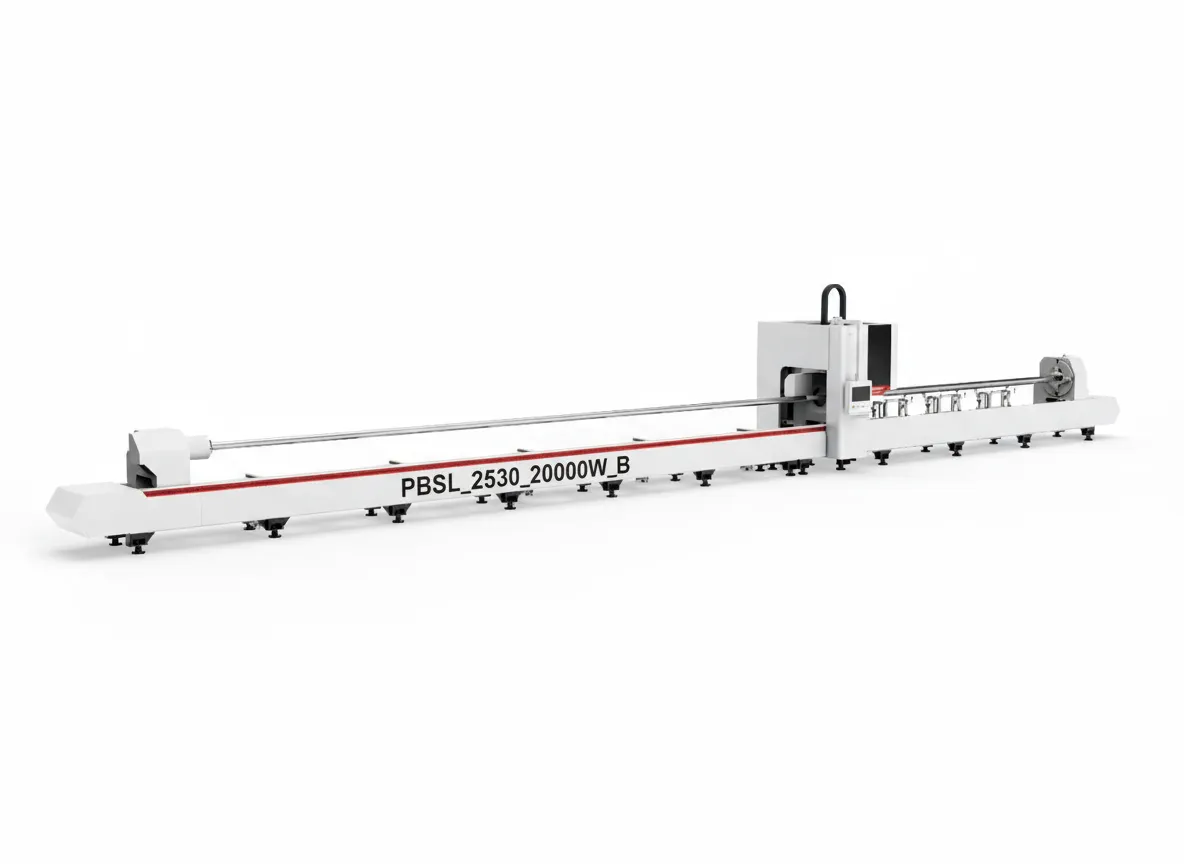

Affordable Precision Lasers That Deliver Beyond Expectations

Welcome to PBLasers Inc., where innovation meets practicality. Our working production showroom showcases state-of-the-art laser technology built to the standards of the biggest brands—but designed to cater to businesses ranging from $1M to $50M in sales.

Whether you’re a small shop or a medium-sized enterprise, staying competitive is no longer a luxury; it’s a necessity. At PBLasers Inc., we understand that every dollar matters, which is why we provide high-quality laser equipment that performs flawlessly without breaking the bank.

Explore Our Laser Systems

Ready to Automate Your Production Line?

Schedule a free, no-obligation demo to see how a PBLasers system can revolutionize your workflow and boost your bottom line.